Due to our brand and our products being required to meet the international OEM standards, we maintain a strict quality control and testing protocol. Said protocol involves but not limited to steps such as:

- PHASE 1: Careful selection of only the best quality materials for assembling the turbocharger such as bar-cut bearings, M2 piston rings, maintaining a consistent material distribution ratio while manufacturing the shafts and compressor wheels.

- PHASE 2: Using oxidation to further increase the hardness and temperature tolerance for the wheels.

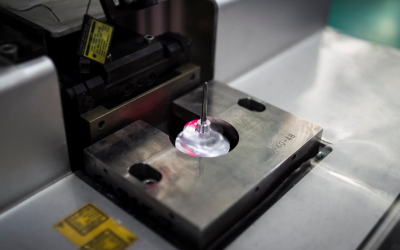

- PHASE 3: Running 3-Stage Axis balance tests for both the compressor wheels and the shafts individually and then the rotor as a whole.

- PHASE 4: Undergoing a fourth stage axis balancing, along with a Vibration Tolerance Rig Test and an Oil Flow Test to check for any leaks and lubrication within the turbocharger’s inner functions.

- PHASE 5: Final Oil Flow bench test after the actuators are installed in case of turbochargers with actuator operated wastegate systems before giving said specimen a “PASS”.